In depth analysis of the revolutionary application of X-ray technology in the industrial field

With the continuous advancement of science and technology, the application of X-ray technology in the industrial field is gradually demonstrating its strong potential. As a non-destructive testing technology, it plays an important role in non-destructive testing detectors, welding inspections, and industrial CT machines, providing efficient and accurate solutions for industrial production.

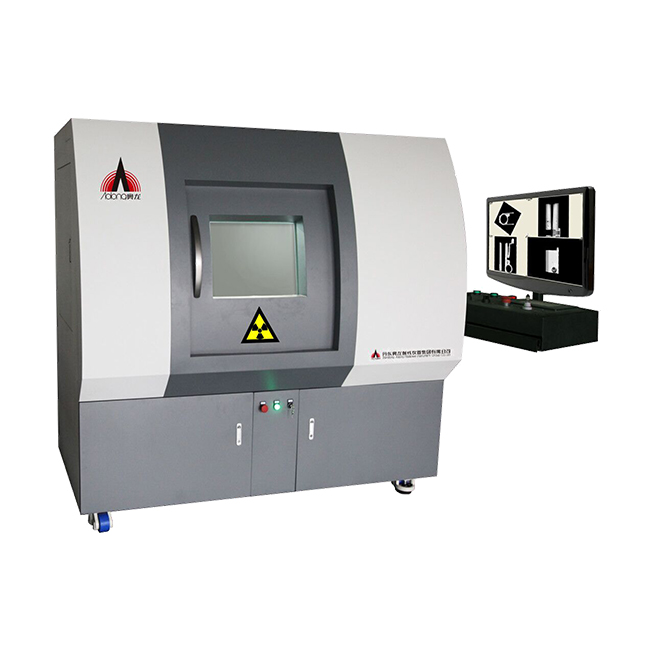

1、 X-Ray non-destructive testing equipment - revealing secrets inside materials

Non destructive testing is one of the crucial processes in today's industrial production. X-ray technology, through its unique capabilities, makes non-destructive testing a more accurate and efficient task. Using X-ray technology, non-destructive testing detectors can penetrate through the surface and deep into the interior of materials, detecting possible defects or damages such as cracks, holes, etc. This meticulous analysis enables engineers to take timely and effective measures to ensure product quality and safety.

2、 Welding Inspection - Ensuring Structural Stability and Safety

Welding is widely used in industrial production, but the stability and safety of welding quality have always been the focus of engineers' attention. X-ray technology can effectively solve these problems. By using welding inspection equipment, workers can conduct comprehensive and accurate inspection and analysis of welds using X-rays. Not only can potential welding defects be discovered, but also the integrity and structural stability of the weld seam can be evaluated. The precision and reliability of this welding inspection provide a solid foundation for engineering projects in various industries.

3、 Industrial CT Testing - A Glimpse into the Secrets Behind the Scenes

Computed Tomography is a powerful tool based on X-ray technology that enables us to obtain internal structural information of objects at very high resolutions. By placing an object in a CT device, the X-ray beam scans the object in different directions and generates a three-dimensional image based on this data. Industrial CT equipment is widely used in fields such as component inspection, material analysis, and product design. It can not only detect small defects and hidden areas, but also provide detailed 3D images, allowing engineers to have a deeper understanding and improve product design and manufacturing processes.

In this information age, the application of X-ray technology in the industrial field is gradually attracting widespread attention. Equipment such as non-destructive testing detectors, welding testing, and industrial CT machines provide engineers with a window to explore the mysteries inside materials. Through accurate and reliable data analysis, industrial production processes become more efficient and safe. With the continuous development and innovation of X-ray technology, we have reason to believe that it will continue to drive the industry towards more advanced and sustainable directions.