Electricity knowledge | Live detection! How to Prevent Power Equipment from X-ray Testing

Firstly, what is live detection?

Live detection: Special testing is conducted on the electrical equipment through dedicated testing equipment and instrument devices to detect potential faults in the operating electrical equipment. Only detect the operating status of electrical equipment during the testing period, only conduct electrical testing, and do not conduct relay transmission testing.

http://www.aolongxray.com/product-list/directional-x-ray-flaw-detector

X-ray testing for live testing

The method of making judgments on the quality, size, characteristics, etc. of the tested equipment based on the composition, density, thickness, and other differences in the absorption and scattering of radiation generated by different media. A non-destructive testing method that uses X-rays to penetrate and attenuate materials to detect defects within them.

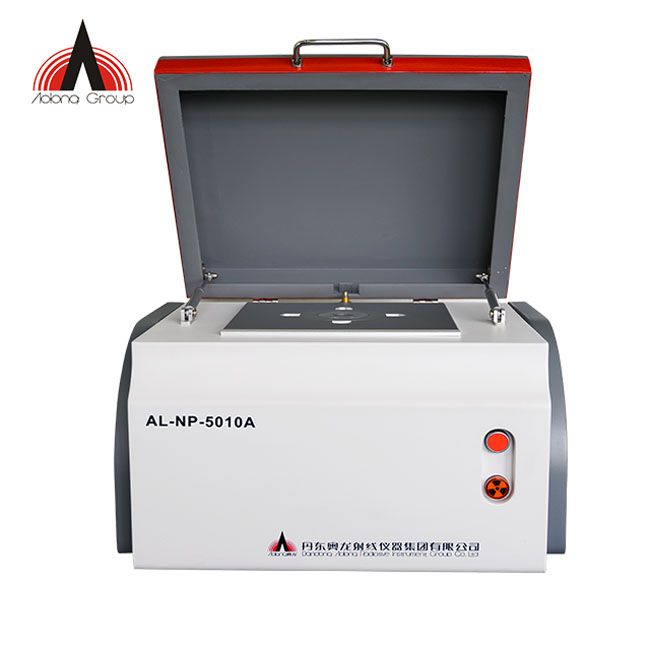

http://www.aolongxray.com/product-list/x-ray-fluorescence-spectrometer

The imaging is intuitive and can be stored for a long time. The detection sensitivity is high, and it is sensitive to volumetric defects. The plane distribution of defect images is true, and the size measurement is accurate. There are no strict requirements for the surface finish of the tested object. The grain size of the material has little effect on the detection results and can be applied to the detection of internal defects in various materials.

http://www.aolongxray.com/product-list/industrial-ct

The X-ray method can intuitively display the size and shape of internal defects in the workpiece, making it easy to determine the nature of the defects. The X-ray film can be used as the original record for inspection and long-term preservation by multiple parties. However, this method consumes high equipment costs such as X-ray film, and the inspection speed is slow. It is only suitable for detecting volumetric defects such as pores, slag inclusions, shrinkage holes, and porosity, and can be qualitative but not quantitative.

http://www.aolongxray.com/product-list/x-ray-pipeline-crawler

At present, it is widely used in the detection of metal fittings in transmission lines, internal impurities or air gap defects in cable joints, and internal defects in substation composite appliances in the field of power. It is more intuitive for structural deformation, air gaps, and impurities.

To learn more, please click on:http://www.aolongxray.com/