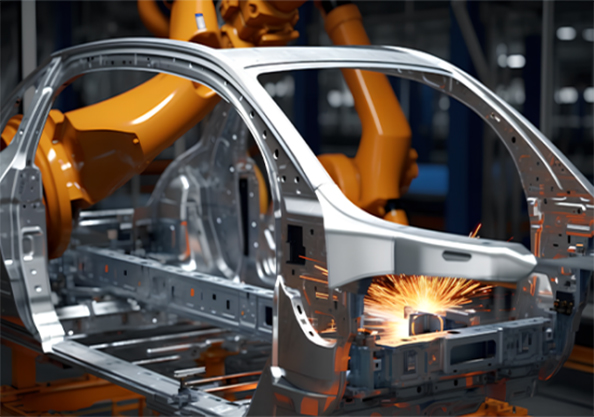

Application of Industrial CT Detection System in the Field of Automotive Parts Inspection

Today, we bring you a hot topic about the automotive industry - the application of industrial CT detection systems in the field of automotive parts inspection. With the continuous development of automotive manufacturing technology and consumers' pursuit of safety and quality, the use of efficient and accurate detection methods has become increasingly important. Industrial CT detection systems, with their unique advantages, have become a necessary tool for car companies.

High precision detection to ensure quality

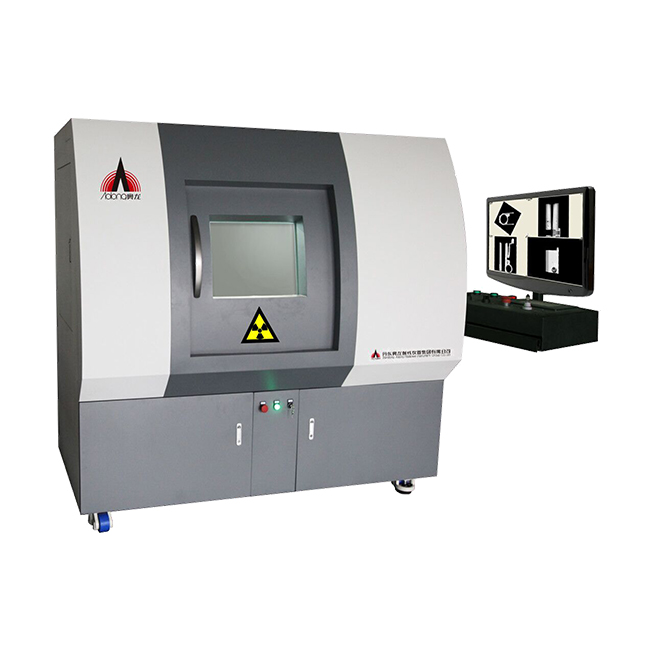

The industrial CT detection system can perform high-precision inspection of automotive parts through non-destructive 3D detection methods, ensuring that their quality meets standards. This system combines X-ray imaging technology and computer reconstruction algorithms to achieve seamless scanning of the interior and exterior of the parts. By obtaining a large amount of data, engineers can quickly analyze and evaluate the internal structure, pores, cracks, and other defects of the parts to ensure their safety and reliability. The industrial CT detection system not only improves production efficiency, but also reduces quality control costs.

Comprehensive coverage and wide application

The industrial CT detection system is widely used in the field of automotive parts inspection. It can accurately detect key components such as engine parts, braking systems, suspension systems, and transmissions. Taking the engine as an example, the industrial CT detection system can help engineers detect the internal structure of the engine cylinder block, confirm whether the matching process between components is qualified, and whether the engine cooling channel is unobstructed. In terms of braking and suspension systems, the industrial CT detection system can accurately detect defects such as size, porosity, and cracks of components, ensuring the safety and reliability of the car's braking and suspension systems.

Unconventional defect detection enhances competitiveness

In addition to conventional defect detection, industrial CT inspection systems can also detect some very common defects, enhancing the competitiveness of automobile manufacturers. For example, it can detect hidden defects and internal texture differences of components, as well as foreign objects wrapped inside parts. This is crucial for ensuring the consistency of automobile appearance and interior decoration, and is also an important part of improving automobile quality and user experience. Industrial CT inspection systems not only help automobile manufacturers avoid potential quality problems, but also improve the overall quality level of products.

The application of industrial CT detection system in the field of automotive parts inspection provides efficient and accurate quality control methods for automobile manufacturers. Through its use, we can better protect the safety and rights of consumers and improve the overall quality level of the automotive industry. In addition, industrial CT detection system also saves time and costs for automobile enterprises, and helps them achieve sustainable development. We believe that with the continuous progress of technology, industrial CT detection system will play a more important role in the future, bringing more breakthroughs and progress to the automotive manufacturing industry!