High Power Industrial CT

It is composed of the high frequency and constant voliage x-raysource, digital flat panel detector, and high precision mechanicalinspection table. The system not only displays the CT chip and 3Dimages of the inspected object, but also with 2D real-time imaginginspection. It has the advantages such as compact, high speedinspection, high resolution images, accurate inspection and high ratioof performance to price. So it is widely used for NDT inspection andmeasurement in aerospace, aviation, military, machinery. casting. IT.automobile field, etc.

http://www.aolongxray.com/product-list/industrial-ct

Main Functions

●Using cone beam CT scan and DR inspection mode, based on the

measurement of the object, it can get thousands pieces tomographicimages at one time.

●The system with the highest possible flexibility for individual customerrequirements.

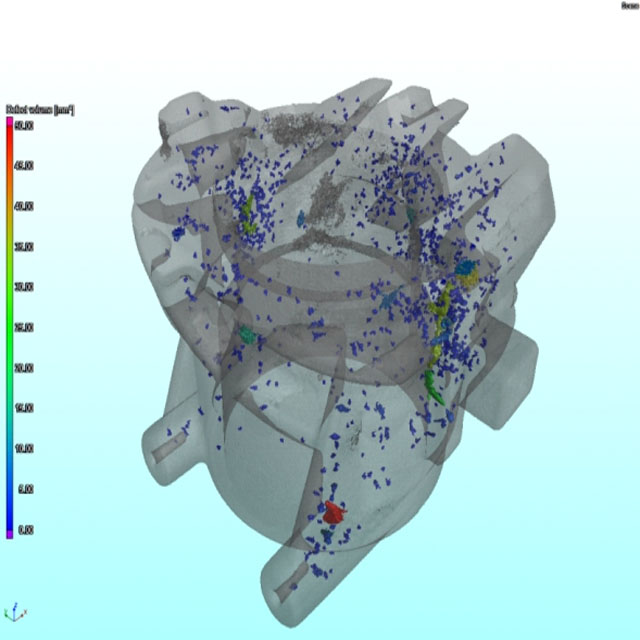

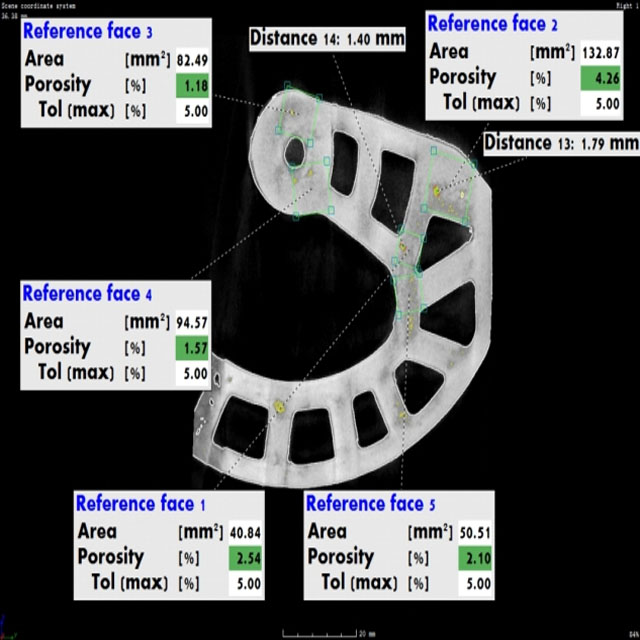

●The system can analyze defect and pore to support ROl scan.

●Mark defect's volume, size and position by the different color.

●Analysis of wall thickness: mark the analysis results in different color.

●Measure the position, distance, radius, angle and other parametersof the object.

●Reverse engineering by GAD design compared with the physicalobject.

●Segmentation tool: data centralization, segmentation according tomaterial and geometry.

●Achieve accurate measurement of internal dimensions of the object.

Main Parameters

●Tube voltage: 20kV-450kVFocus size: 0.4mm

●Density resolution: 0.5%

●Scan mode: cone beam scan

●Detector; digital flat detector or linear detector

http://www.aolongxray.com/ website