Internal defect detection of soft pack power battery

The internal defects of soft pack power batteries mainly include: poor quality of reinforcement, foreign objects in battery cells, bubbles, poor bonding, uneven spacing between reinforcement, poor conductivity, and other issues. If these defects cannot be detected in a timely manner, they will pose great risks to the use of batteries, and even lead to battery failure, thereby affecting the safety of vehicle driving.

There are currently several methods for detecting internal defects in soft pack power batteries, including:

1. Positive negative charge method: The charged battery is decomposed and subjected to optical inspection, and the damage to the battery electrodes and separators is observed and recorded through an optical microscope.

2. Microwave method: Microwave detection is performed on separators, electrolytes, and electrodes, as different materials have different reflections and absorptions of microwaves, which can detect defects and faults inside the battery.

3. Magnetic resonance imaging method: With the help of nuclear magnetic resonance imaging technology, the internal structure and chemical reactions of the battery can be accurately imaged, and various hidden defects can be discovered.

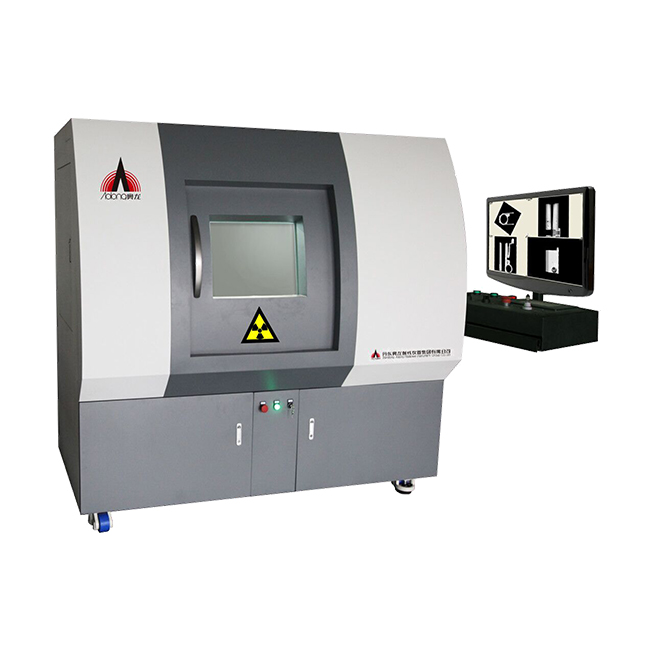

4. X-ray detection method: X-ray transmission imaging technology can directly observe the structure and composition inside the battery, and discover hidden defects. And after multiple studies, it has been proven that X-ray transmission imaging technology is a reliable and non-destructive method for detecting internal defects.

Among the four methods mentioned above, X-ray detection is the most popular and popular method because it can directly scan the soft pack power battery through the packaging material, quickly and accurately identifying various defects inside the battery.

With the continuous improvement of detection technology, the detection of internal defects in soft pack power batteries is correspondingly more reliable and efficient. However, the quality issue of soft pack power batteries remains a bottleneck for new energy vehicles, requiring manufacturers and testing institutions to work together to solve it and safeguard the development of new energy vehicles.

In short, internal defect detection of soft pack power batteries is an important link in ensuring battery quality and safe driving of new energy vehicles. The application of X-ray detection technology in the field of battery internal defect detection has been widely recognized due to its non-destructive, efficient, and accurate advantages. We believe that with the advancement of technology, the detection of internal defects in soft pack power batteries will become increasingly sophisticated, injecting new energy into the development of new energy vehicles.