The application prospects of X-RAY detection in the pan industrial field

Industrial X-RAY testing equipment belongs to a type of non-destructive testing equipment. Non destructive testing, as the name suggests, is a general term for all technical means that use the characteristics of sound, light, magnetism, and electricity to detect whether there are defects or unevenness in the tested object without damaging or affecting its performance. It provides information on the size, location, nature, and quantity of defects, and then determines the technical status of the tested object (such as qualification, remaining life, etc.).

The X-RAY detection equipment in the industrial field can be applied to detect metal castings (including automotive parts, industrial machinery parts, rail transit wheels, etc.), sensitive structural components (such as weapons, aerospace parts, etc.), pressure vessels (such as high-pressure boilers, gas cylinders, gas cylinders, etc.), pipe welding and other scenarios.

At present, there are over 2000 professional institutions and service units (companies, inspection institutes, inspection stations, inspection centers, etc.) engaged in non-destructive testing in China, including more than 300 certified institutions approved by the Special Equipment Inspection Association. There are over 800 manufacturers and units involved in the manufacturing of relevant non-destructive testing equipment and materials. The total annual sales of non-destructive testing instruments and equipment is about 3 billion yuan, and together with third-party non-destructive testing business, the total market capacity related to non-destructive testing technology is about 6 billion yuan. As an important non-destructive testing method, X-RAY testing has irreplaceable advantages and will have great potential in industrial non-destructive testing in the future.

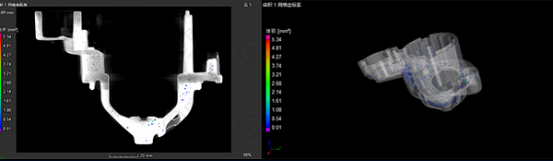

The Aolong Industrial X-RAY real-time imaging detection system and industrial CT detection system play a crucial role in automotive parts inspection, casting inspection, and weld inspection. The Aolong system can flexibly adapt to individual requirements, coordinate and cooperate with each other, and meet various testing needs such as offline sampling inspection, online 100% full inspection, small workpiece inspection, small and medium-sized workpiece inspection, medium and large workpiece inspection, thin-walled lightweight workpiece inspection, and gray cast iron inspection with a thickness of several centimeters for casting products. It can quickly and accurately detect various defects in tires, wheels, and other castings, effectively ensuring the quality and safety of products.

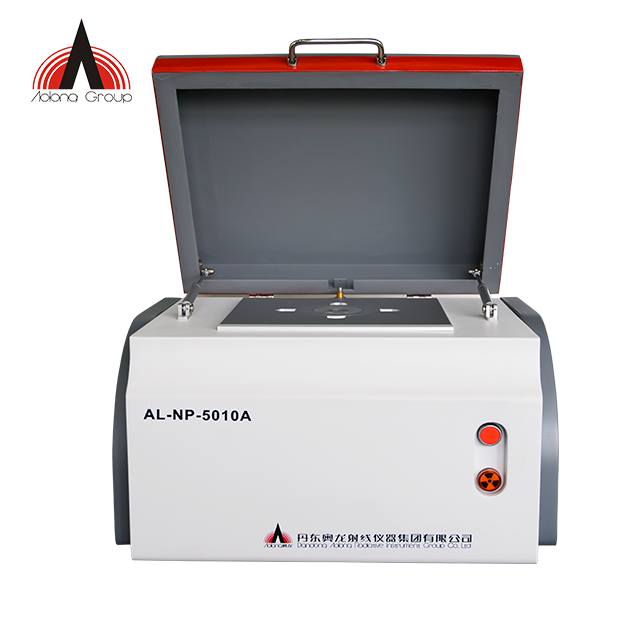

The product includes an X-RAY system suitable for installation in a radiation detection lead room, a universal X-RAY detection system based on fully shielded equipment, and customized solutions for different customers. If the application requirements exceed the capabilities of conventional devices, the Rilian Technology team will tailor a system for the enterprise to meet your testing needs.