X-ray DR imaging principle

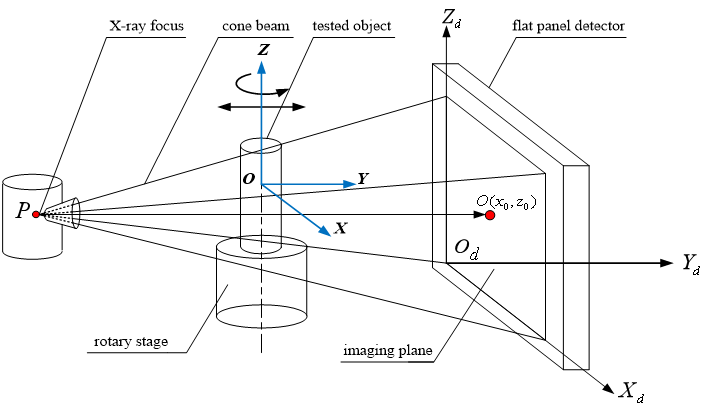

DR system is generally composed of X-ray source, tested object, flat panel detector, image workstation and etc.

For DR detection technology, its core component is the detector. At present, there is one kind of detector used in engineering, amorphous silicon flat panel detector.

Amorphous silicon flat panel detector adopts large-scale integration technology, integrating a large area amorphous silicon sensor array and cesium iodide scintillator, which can directly convert X-photons into electrons and finally convert them into digital signals through digital analog converter (ADC). Flat panel detector has the characteristics of large dynamic range and high spatial resolution, which can realize high-speed DR detection, and has become the mainstream of industrial DR detection technology development.

The X-ray generated by the X-ray source constitutes the incident field strength, which is attenuated by the test piece to obtain the transmission field strength, and then the transmission field strength acts on the detector to finally output the image. When the X-ray of the incident field intensity shines on the test piece, the X-ray photons interact with the material atoms of the test piece, including the photoelectric effect, compton effect and coherent scattering. The final result of these interactions is that part of the X-ray photons are absorbed or scattered, that is, the X-ray photons are attenuated when passing through the material. The actual attenuation process is related to the X-ray energy, material density and atomic coefficient.