X-ray real-time imaging detection equipment for detecting casting defects

Casting technology is one of the basic technologies in modern mechanical manufacturing industry, widely used in various industrial production fields such as automotive parts, medical devices, engineering machinery, hardware products, aerospace, etc.

As an important basic industry in the mechanical industry, with the rapid development of information, improving the production efficiency and quality of casting will be a topic that many casting workers must face. The high scrap rate of casting blank products has always been a common problem in the industry. How to better control the quality of castings and improve the casting process is particularly important!

Due to the complexity of the casting process, there are many factors that affect the quality of castings. The raw material control is not strict, the process plan is not reasonable, the mold structure design is not reasonable, and the production operation is improper, resulting in various defects in the casting. Common defects include inclusions, bubbles/pores, looseness, and cracks. In order to ensure the quality of castings and save costs, it is necessary to detect defects in a timely manner in the early stages of the production process. X-ray non-destructive testing has become the preferred method for casting defect detection, as it can avoid material waste and improve production efficiency. At present, NIO Technology's casting X-ray intelligent testing equipment has provided testing services to multiple die casting manufacturers both domestically and internationally. The research and development of mechanical, electrical, and image processing software have obtained multiple national invention patents and software copyrights.

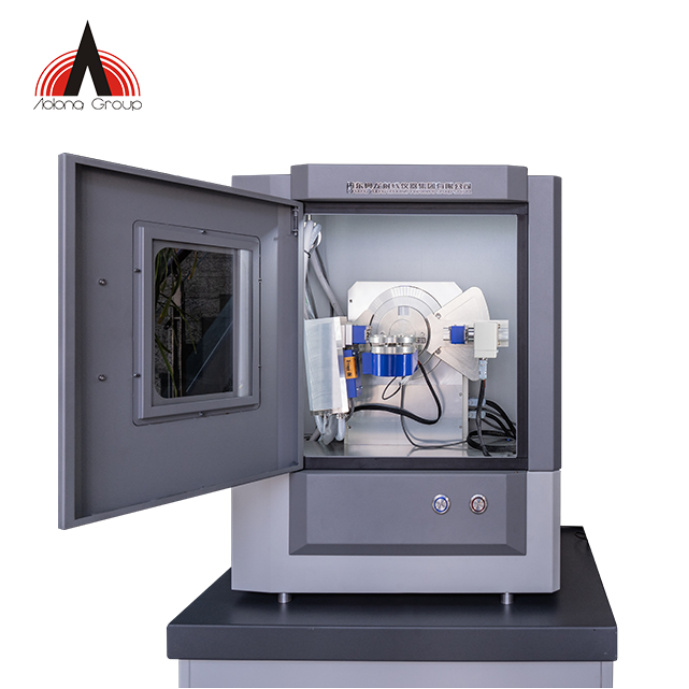

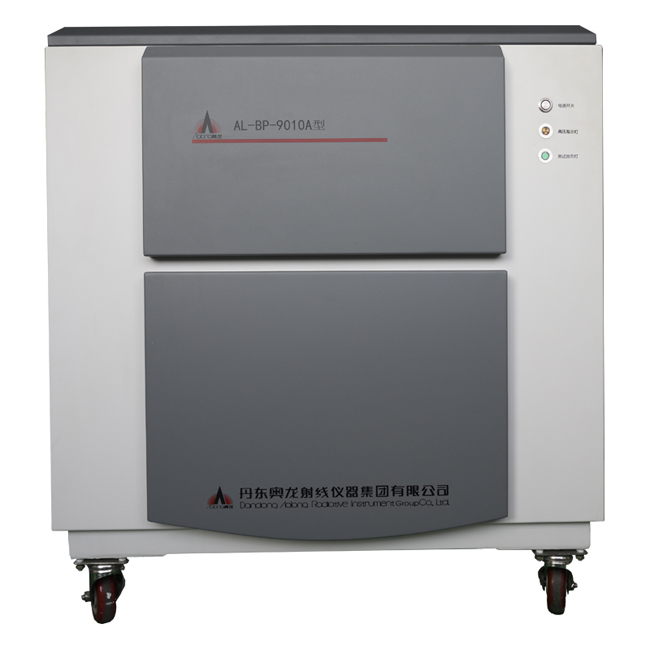

X-ray real-time imaging detection equipment is suitable for the detection of small products such as aluminum castings, iron castings, automotive parts, hardware products, oak, plastic products, ceramics, etc. Image processing software has advanced functions such as automatic measurement and defect detection, automatic product quality recognition, and image optimization. The software can automatically calculate the position, size, and area ratio of the workpiece based on the product judgment standards set by the user, and automatically determine whether the product is qualified.

X-ray real-time imaging detection equipment has advantages such as comprehensive detection angle, automatic defect calculation, automatic product quality judgment, clear detection images, high motion accuracy, high integration, high cost-effectiveness, small size, and beautiful appearance. It will be a high-quality choice to ensure product quality and improve the production process.