Industrial CT Equipment: A Sharp Tool Leading the New Era of Non destructive Testing

With the updating and iteration of manufacturing technology, the industrial manufacturing industry has increasingly strict requirements for product quality, and traditional testing methods can no longer meet their efficient and high-precision testing needs. Industrial CT equipment has emerged in the field of industrial non-destructive testing, following 2DX-ray technology. With its unique advantages and excellent performance, it has become a "new favorite" in the field of industrial non-destructive testing. The transformation from 2D testing to 3D testing is very rapid.

The computer tomography system (hereinafter referred to as industrial CT) is based on the attenuation and absorption characteristics of radiation in the tested object. Under the premise of no damage to the sample, two-dimensional tomographic images are collected, and then software is used to synthesize three-dimensional images, which intuitively, clearly, and accurately display the structure, defects, dimensions, and other product information of the tested sample.

In 2023, China solved the pain points of controlling and monitoring complex internal structural defects in batteries through 360 ° all-round X-ray transmission and high-speed customized CT reconstruction technology, ensuring the accuracy of stacking. After high-density stacking, 100% of CT high-speed full inspection was carried out, preventing the flow of defective products on the production line. It is reported that China's industrial CT equipment has become a leader in the market due to its precise, efficient, and stable performance. So, what are the advantages of industrial CT equipment reflected in?

1、 High precision

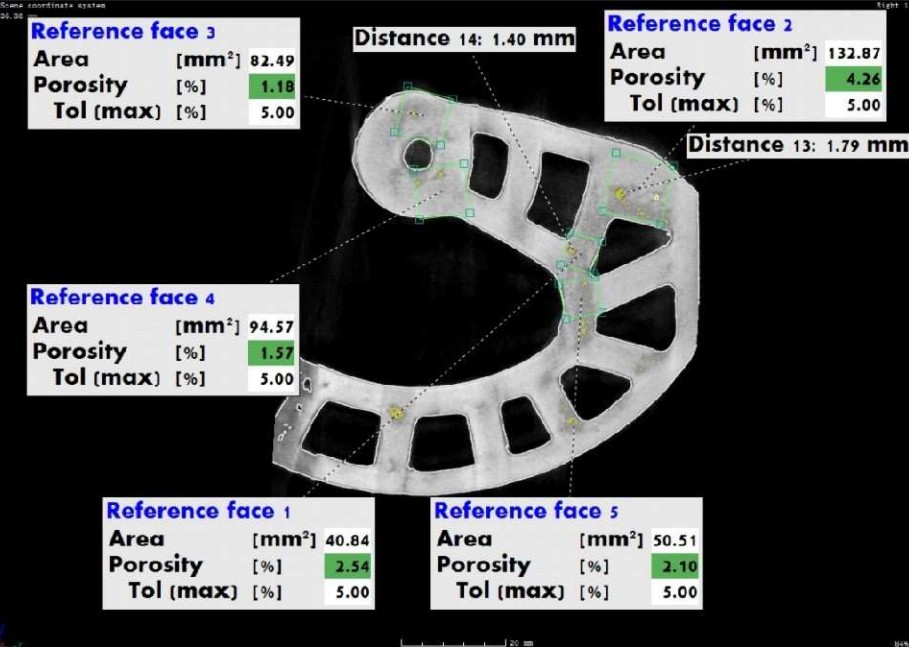

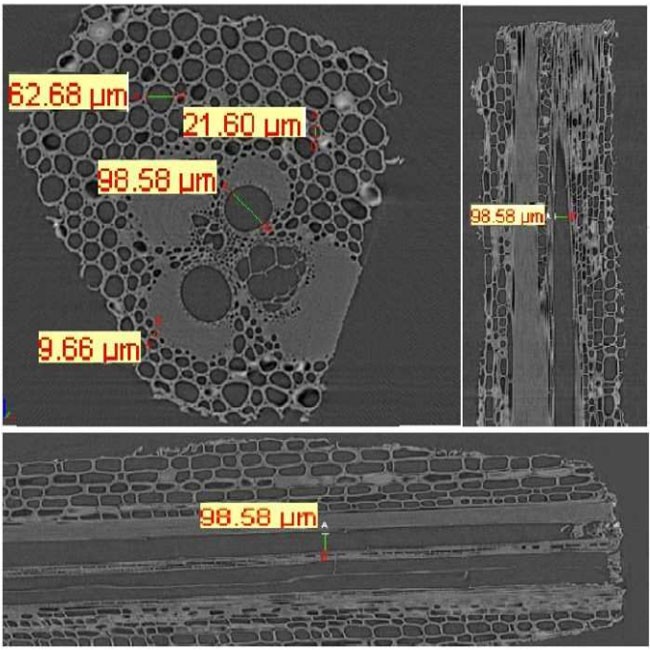

Industrial CT equipment can achieve high-precision 3D imaging. The equipment is equipped with high-precision radiation sources and detectors, and is equipped with a precise mechanical motion control system to ensure the accuracy and stability of the scanning process. The generated 3D images have extremely high spatial and density resolution, which can clearly display the internal structural details of the tested item and accurately capture small defects inside the product.

2、 True restoration

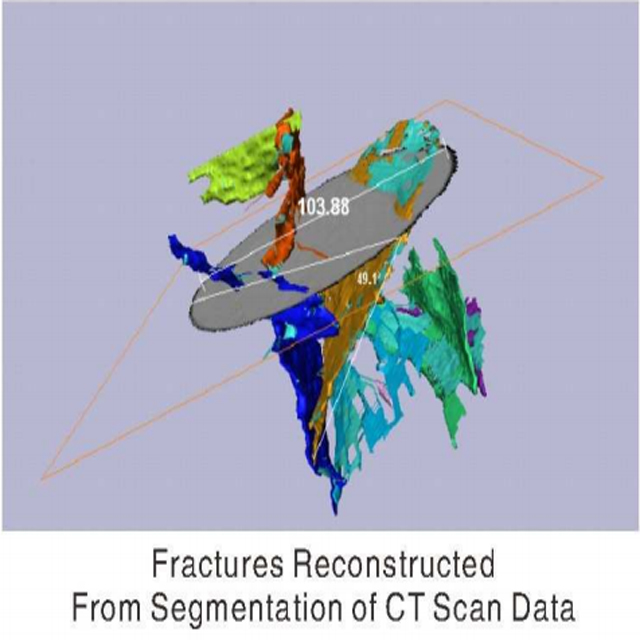

Through all-round and multi-dimensional scanning, industrial CT equipment can obtain rich information inside objects, thereby constructing realistic and accurate 3D models. This model can realistically display the internal structure and material situation of the sample, providing users with an intuitive and comprehensive product view. In addition, 3D imaging is particularly effective in detecting internal defects in products. Whether it is pores, slag inclusions, cracks, or lack of fusion, they can be visually displayed in 3D images, making it convenient for users to make accurate judgments and evaluations.

3、 Easy to operate

The operability of the equipment is also very important for users. Industrial CT equipment is convenient to use, and users can easily carry out detection tasks through the software interface. During the scanning process, users can preview the 3D imaging process in real-time and dynamically manage the scanning area to ensure imaging quality; Through the accompanying software interface, it is easy to rotate, scale, and translate 3D images, observe the internal structure of the product from different perspectives, and achieve comprehensive visual inspection; The software also provides a large number of measurement tools, which can be used for size measurement and defect annotation on 3D images for report writing and data analysis.

4、 Widely applicable

High precision industrial CT equipment is mainly used for non-destructive testing of complex materials and structures. In the aerospace field, complex components can be accurately inspected to ensure the safety performance of the aircraft; In the field of automotive manufacturing, industrial CT equipment can quickly detect defects in automotive components, improve product quality and competitiveness; In the field of electronic manufacturing, industrial CT can inspect the internal structure of small components such as circuit boards and chips, providing strong support for product development and production. The three-dimensional imaging function of high-precision industrial CT equipment not only improves detection efficiency and accuracy, reduces the risk of misjudgment and missed detection, but also enhances the evaluation level of product quality. Through intuitive and comprehensive 3D images, users can easily understand the internal situation of the product, providing a reliable basis for subsequent decision-making and improvement.

Overall, the competitive landscape in the field of X-ray intelligent detection equipment has put forward high development requirements for domestic enterprises, and enterprises that prioritize mastering 3D/CT detection technology undoubtedly have taken the lead in grasping the future development trend of the market, thereby gaining greater industry competitiveness.