Industrial non-destructive testing ensures safe production of industrial equipment

In the city where we live, there are thousands of industrial equipment. Once these large-scale equipment fail, they will face high maintenance costs, and the cessation of operation of the equipment supporting production line will bring huge economic losses. In addition, industrial equipment also carries the risk of safety accidents, which may threaten personal safety.

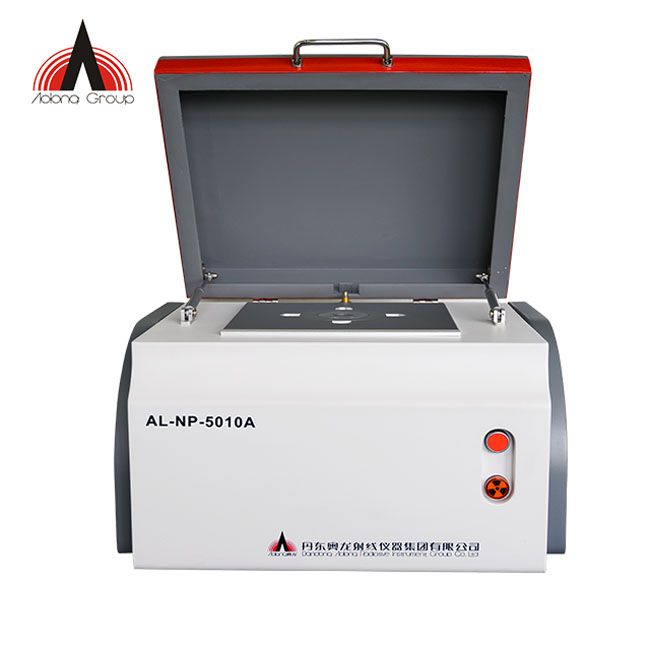

Industrial equipment should also undergo physical examinations. In the field of industrial equipment, industrial "doctors" use the special properties of materials such as sound, light, magnetism, and electricity to conduct "physical examinations" on equipment through some technical means or auxiliary instruments, detecting the structure, properties, and status of the interior and surface of objects, identifying the types, quantities, shapes, positions, sizes, distributions, and changes of defects, and formulating response measures based on the test results. This method is known as non-destructive testing in the industry. X-ray detection utilizes the characteristic that X-rays can penetrate objects, and the degree of attenuation after X-ray penetration varies in objects of different materials or densities. When there are defects in the local area inside the inspected workpiece, there will be a significant difference in the attenuation degree of X-rays penetrating the defect area compared to the normal area. By using a special detector to receive the transmitted X-rays and form digital images of different grayscales, we can accurately and intuitively determine whether there are structural defects in the workpiece, as well as the location and size of the defects.

The principle of industrial X-ray testing equipment is the same as that of X-ray machines used in hospitals, but the material composition of industrial products is greatly different from that of human tissues, and the related instruments, testing processes, and requirements are naturally different. Most non-destructive testing of industrial equipment requires higher accuracy than medical testing. Leakage of millimeter or even micrometer level equipment defects during use may lead to safety accidents.

Regular hazard investigation and daily maintenance of industrial equipment are particularly important. With this group of industrial "doctors", safety production can be assured!