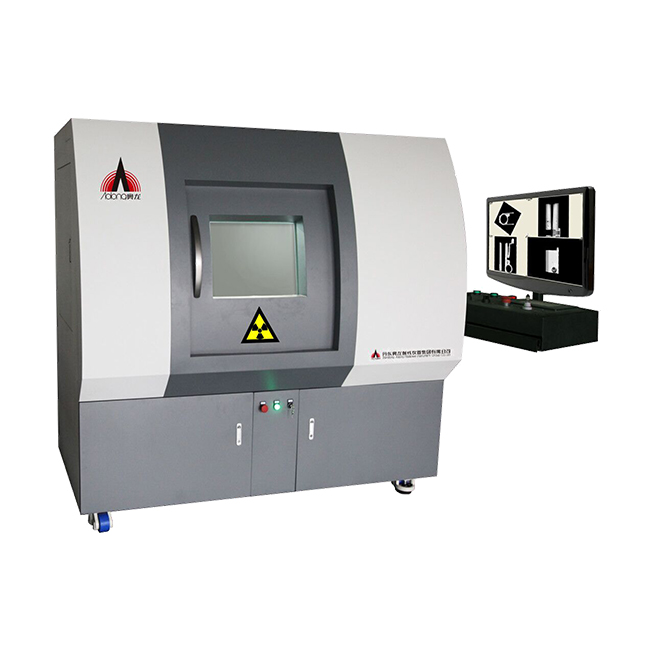

Industrial Digital Radiography X Ray Ct Scan

- Aolong

- China

- 15 days

- 80pc/year

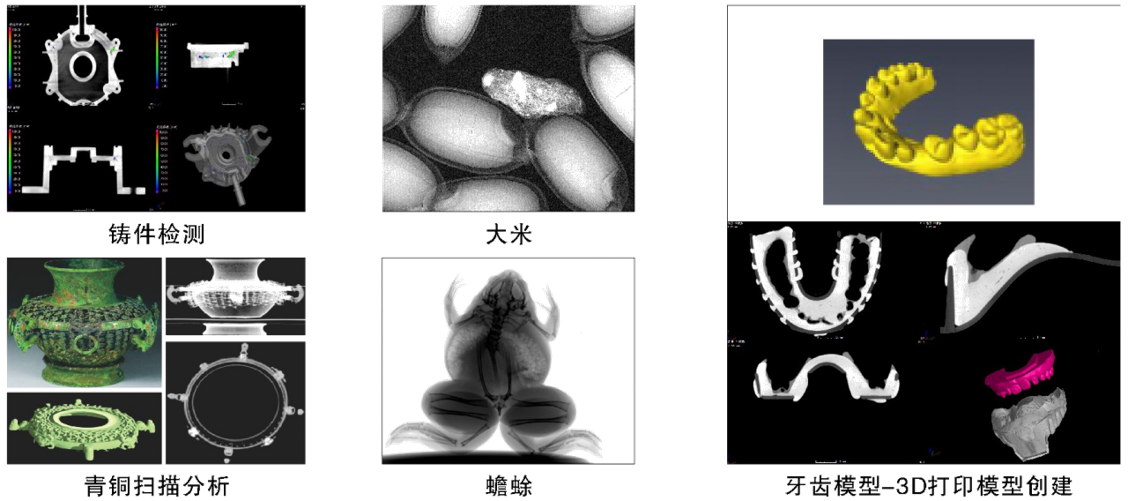

This system supports 2D and 3D inspection based on computertomography technology with automatic defect recognition inspection,material analysis, reverse engineering function and others. The systemis ideal for inspecting metal, ceramics, core,complex casting part,plastic parts, auto parts, jewelry, new material and semiconductor, etc.lt is widely used in 3D print technology, biological research, medicine, aerospace, machinery, electric, ship, military, material, geology,archaeology and others.

Main Functions

● Using cone beam CT scan and DR inspection mode and it can obtainthousands of pieces tomographic images by one time.

● x-ray source suits small objects inspection.

● lt can be place on the table.

● lmaging mode: 2D,3D

● The system can analyze defect and pore, support ROl scan.

● Use different color to mark defect's volume, size and position.

● Count and analyze defect dimension, calculating pore ratio, and generatepore volume histogram.

● Analysis of wall thickness: use different color mark the analysis results.

● Measurement tools: measure position,distance,radius angle and otherparameters of the object.

● Reverse engineering: CAD design and compare with physical object.

● Segmentation tool: data centralization, segmentation according to materialand geometry.

● Achieve accurate measurement of internal dimensions of the object.

● Fiber composite material analysis function

● Comparison function between design and object

Main Parameters

Tube voltage | 20kV~90kV |

| Focus size | 5μm |

| Spatial resolution | 3μm |

| Density resolution | 0.3%~0.5% |

| Scan method | cone beam scanning |