Micro focus industrial CT

- Aolong

- Dandong

- within 1 month

- 500pcs one month

1. Micro Focus X-Ray CT System imaging is exceptionally clear, making it suitable for inspection scenarios requiring high precision.

2. The Micro Focus X-Ray CT System has a compact structure, fast scanning speed, and can perform batch inspections.

3. Micro focus industrial CT equipment offers multiple functions yet is easy to operate, and its maintenance costs are also very friendly.

Product Introduction of Micro Focus X-Ray CT System:

Micro focus industrial CT equipment is a small, high-precision 3D imaging device that can "see through" the interior of materials. Micro focus industrial CT equipment works on a similar principle to a CT scanner in a hospital, but with much higher clarity. It can scan internal details of metals, plastics, and ceramics that are completely invisible to the naked eye, and can directly generate 3D models for easy viewing. For complex, non-destructible components, Micro focus industrial CT machine is practically a "X-ray vision tool," capable of detecting defects and performing structural measurements, making it an indispensable inspection tool for many engineers.

Product Features of Micro Focus X-Ray CT System:

The biggest feature of Micro focus industrial CT equipment is its ability to "clearly see even the smallest details." Micro focus industrial CT equipment has an extremely small focal spot, resulting in exceptionally high resolution, clearly capturing minute issues such as internal microcracks, micropores, and material inhomogeneities. The scanning angle is also flexible, allowing for full-angle rotation scanning of the sample to generate raw 3D volumetric data. Micro focus industrial CT machine typically also features automatic calibration and reconstruction functions, making it easy to operate.

Product Advantages of Micro Focus X-Ray CT System:

The advantage of Micro focus industrial CT machine is that it can replace destructive testing. Micro focus industrial CT machine can obtain complete information about the internal structure of parts without cutting or disassembling, saving time, effort, and product waste. Micro Focus X-Ray CT System's measurement accuracy is very high, making it suitable for dimensional inspection. It is more accurate and intuitive than traditional methods such as manual measurement and caliper measurement. In addition, the 3D data can be exported to CAD for comparison, making quality problems immediately visible and resolving them with exceptionally high efficiency.

The system can be equipped with an X-ray source with a resolution of 160kV or above at the micrometer level, as well as a high-energy open type micro focal point line source, with a maximum energy of 300KV and a minimum JIMA resolution of 0.5 micrometers.

This system is ideal for detecting homogeneous metals, ceramics, plastics, rock cores, complex castings, and semiconductors. Widely used in aerospace, automotive parts manufacturing, machinery, electrical, shipbuilding, weapons, materials, geology, archaeology, and many other fields.

Performance characteristics

● Open micro focus ray tube, with high precision, longer service life, and more stable performance.

● 3D volumetric CT.

● A sturdy marble base ensures the stability of the equipment.

● High precision bearing technology and linear guide rail system ensure high-precision measurement.

● The external design of the equipment is compact, simple and generous, with a small footprint.

● Automatically and quickly detect, analyze, and display internal defects or pores.

● Analyze the volume, location, size, and surface area of each defect.

● Identify defects with colors based on their volume size.

● Analyze and statistically analyze the entire object or user specified "ROI", including defect size, total porosity percentage, and porosity volume.

● The data interface allows the analysis results in the software to be exported.

● Scanning method: Cone beam, spiral optional.

● Radiation safety is better than 1 μ Sv/h.

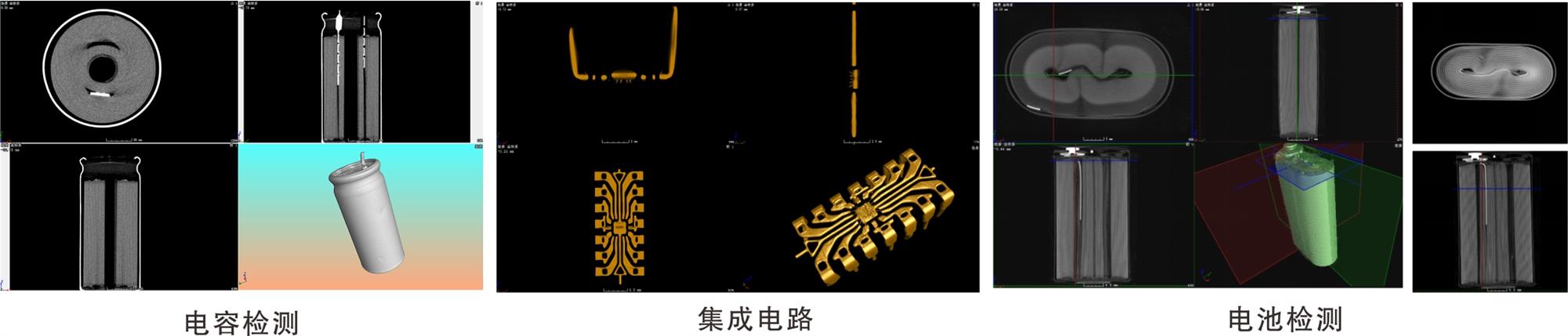

Detection instance

About Us:

Dandong Aolong Group is located in the Dandong Port Industrial Park, Liaoning Province, covering an area of 30,000 square meters with a building area of 17,000 square meters. As a leading enterprise in China's X-ray instrument manufacturing industry, we possess a highly skilled and experienced R&D team, as well as complete modern production and testing equipment. For over 50 years, the company has focused on Micro focus industrial CT machine and continuously promoted technological innovation. Our products are widely used in defense, aerospace, shipbuilding, automotive, metallurgy, chemical and other industries, and are exported to more than 60 countries worldwide, winning the consistent trust of our customers.