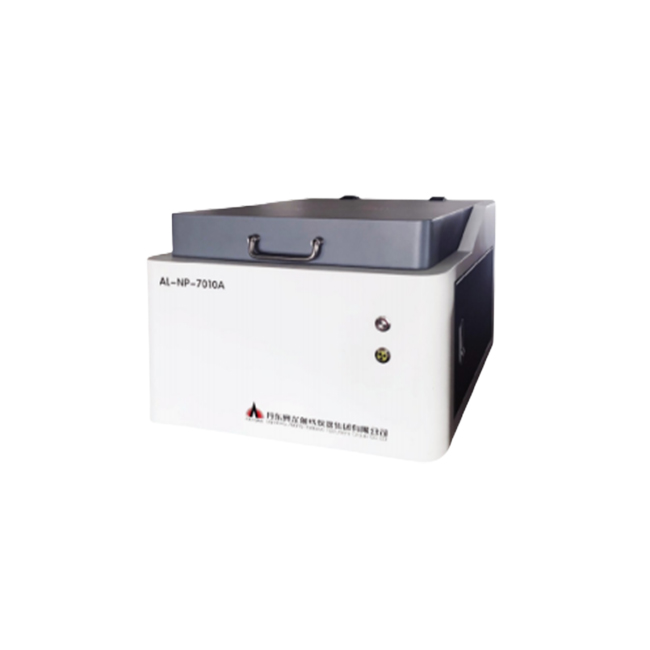

X-ray fluorescence coating thickness gauge (AL-NP-7010)

- Aolong

- Dandong

- within 1 month

- 500pcs one month

The X-ray fluorescence coating thickness gauge is an analytical instrument that uses energy dispersive X-ray fluorescence analysis technology to simultaneously measure multiple elements. It can be configured to analyze and determine any number of elements from Na to U according to user application requirements.

The X-ray fluorescence coating thickness gauge is an analytical instrument that uses energy dispersive X-ray fluorescence analysis technology to simultaneously measure multiple elements. It can be configured to analyze and determine any number of elements from Na to U according to user application requirements. In addition, it is equipped with fully functional testing software and a user-friendly interface to meet the needs of metal coating and element content measurement. The user-friendly design makes testing work more easily completed. This instrument has two functions: measuring element content and detecting coating thickness.

Widely used in thickness measurement of metal coatings, determination of plating solution and plating content, electroplating, hardware, PCB, bathroom, electronic appliances, precious metals and other industries.

Overall performance:

● FAST SDD detector

The resolution of the detector is used to evaluate the energy dispersive X-ray fluorescence spectrometer

One of the main indicators of performance

Resolution<122eV (lower resolution leads to higher sensitivity)

Count rate>1000000CPS

Beryllium window thickness=0.005mm

Detection power<1.2W

●X-ray tube target material rhodium (Rh) or tungsten (W)

Tube voltage 5-50KV

Tube current 1-1000uA

●Multi channel pulse amplitude analyzer (commonly known as spectrometer energy scale)

Number of channels: 2048

●Power controller

System power control+5 VDC at 250 mA (1.2 W)

Constant cooling control 400 VDC

●Low power small side window X-ray generator (commonly known as X-ray tube)

The X-ray tube, which has undergone special treatment with embedded lead inside, is fully shielded, leaving only the side window X-ray exit area. Tank insulation oil is used for high-voltage insulation and cooling, with a 0.005-inch beryllium window standard window, rated power consumption of 50 watts, and rated voltage of 50 kV. Design service life>15000 hours.

● High voltage generator

Input: 85-265Vac, 47-63Hz, power factor correction.

Models ranging from 1kV to 5kV comply with UL85 to 250Vac input standards

Voltage variation rate: 0.01% of output voltage from no load to full load

Current variation rate: 0~rated voltage, 0.01% of output current

Ripple: 0.25% peak to peak of output voltage

Temperature coefficient: voltage or current setting, 0.01%/℃

Stability: 0.05%/8 hours after preheating for half an hour

●Automatic filter conversion system

Automatic filter conversion system: 6 types of filters are automatically selected and converted (filter function: to improve the spectral line energy spectrum composition of the excitation source, used to suppress the strong X-ray fluorescence of high content components in multi-element analysis, and improve the measurement accuracy of the tested element).

● Safety radiation protection system

The redesigned low radiation X-ray tube has undergone special treatment (starting from the source)

Fully enclosed lead plate double-layer anti radiation design (starting from the design structure)

Fully automatic lead plate filter automatic shielding device

Unexpected opening of sample cover with X-ray forced interruption device

Delay testing and X-ray warning system

● Powerful analysis software workstation

One click operation software, simple and easy to use, without the need for professional knowledge.

Humanized human-machine interface

Various testing parameters do not need to be set by operators, and there is a powerful customization report function.

Automatic storage of test data with historical query function.

The most cutting-edge qualitative and quantitative analysis methods.

Can analyze dozens of elements simultaneously.

The element analysis is fast, and the analysis time can be adjusted from 30 seconds to 900 seconds.

Long term standby mode automatically reduces tube pressure and flow, prolonging the lifespan of X-ray tubes.

Temperature control of X-ray tubes to protect them and extend their lifespan.

Real time monitoring of instrument operation status, easy maintenance of the instrument.

To prevent accidental operation of opening the sample cover during sample testing, the software provides warning operation prompts and turns off the high-voltage power supply.

● Types of sample analysis

It can directly detect solids, liquids, and powders without the need for complex sample preparation processes, allowing for non-destructive analysis of samples.

● Professional coating thickness testing

Can analyze single coating, multi coating, and alloy coating.

Analysis methods with multiple coatings.

Analysis thickness: generally 0.05-50um (thickness varies for different elements).