For diameter 219mm~510mm X-ray pipeline welding inspection equipment

- Aolong

- China

- 15 days

- 1500pc/year

The X-ray pipeline welding inspection equipment helps to assure quality in pipeline construction.

The X-ray pipeline welding inspection equipment are easy to operate.

Main Function

The inspection for weldings seams is indispensable for quality assurance in pipelines, whether for steel or other special alloys. Weldings quality in pipes for gas or petrol transportation must be inspected. X-ray welding inspection equipment technology has played a significant role in the field of welding inspection.

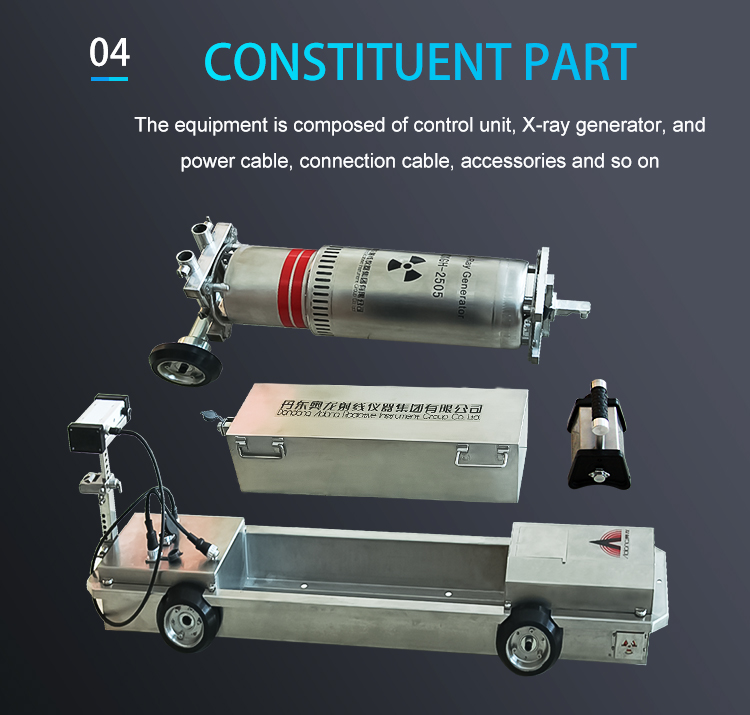

The pipeline welding inspection equipment can be moved in the pipeline with great efficiency because the pipeline welding inspection equipment is controlled by PLC with protecting it from blocking and under voltage. The x-ray pipeline equipment is easy to be separated into several parts and then to be put together, so the x-ray pipeline welding inspection equipment is easy to carry. You can change the exposure parameter and make the X-ray pipeline welding inspection equipment move, stop and have an exposure with the exterior controlling source.

Technical Parameters

| AL-100A | AL-100B | AL-100C | AL-100D | AL-100E | ||

| Item | Parameters | Parameters | Parameters | Parameters | Parameters | |

| Range of Pipe Diameter | φ810-1440mm | φ710-1219mm | φ410-1016mm | φ219-510mm | φ219-510mm | |

| Max.Penetration(A3 Steel) | 42mm | 35mm | 30mm | 24mm | 24mm | |

| Tube(Cone) | Max.Out Voltage | 350kv | 300kv | 250kv | 200kv | 200kv |

| Max.Out Current | 3mA | 3mA | 3mA | 3mA | 3mA | |

| Focal Size | 1.0×2.3mm | 1.0×3.5mm | 1.0×2.0mm | 1.0×2.0mm | 1.0×2.0mm | |

| Beam | 360°×30° | 360°×30° | 360°×30° | 360°×30° | 360°×30° | |

| Environment Temperature | -30°-80° | -30°-80° | -30°-80° | -30°-80° | -30°-80° | |

| Relative Humidity | ≤90% | ≤90% | ≤90% | ≤90% | ≤90% | |

| Energy Capacity of Battery | 120V,20Ah | 110V,22Ah | 106V,22Ah | 110V,10Ah | 96V,10Ah | |

| Crawling Ability | ≤45° | ≤45° | ≤45° | ≤45° | 30°-40° | |

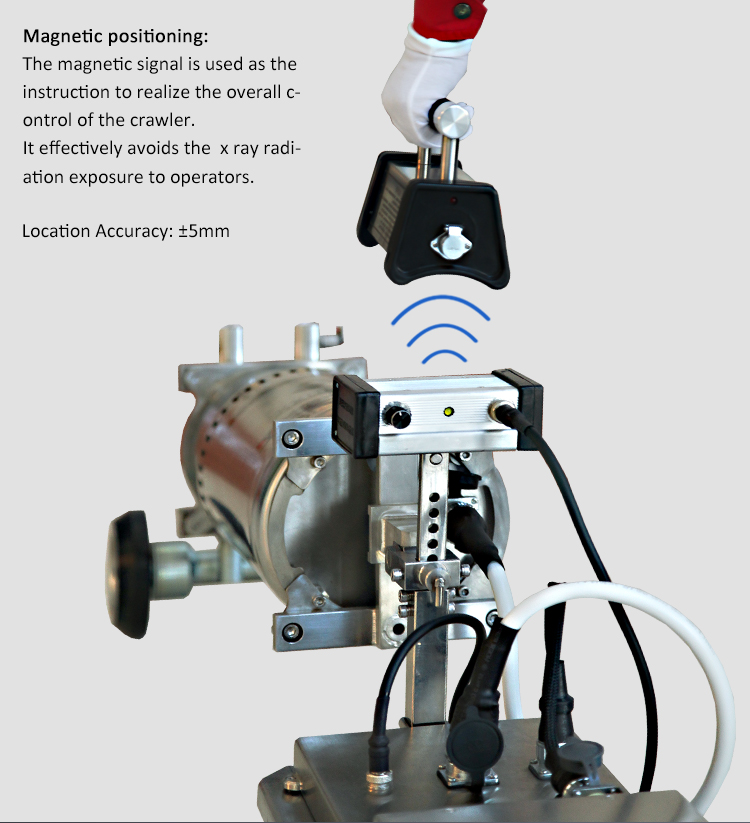

| Location Accuracy | ±5mm | ±5mm | ±5mm | ±5mm | ±5mm | |

| Crawling Distance | 8Km(round trip) | 8Km(round trip) | 8Km(round trip) | 6Km(round trip) | 6Km(round trip) | |

| Crawling Speed | 16-18m/min | 16-18m/min | 16-18m/min | 16-18m/min | 16-18m/min | |

| Dimension (Crawler Vehicle) | 1400×400×219mm | 1250×270×180mm | 1200×300×190mm | 1180×230×160mm | 1600×140×140mm | |

| Tuming Radius | >70° | >70° | >70° | >70° | ≥10D | |

| Total Weight | 165Kg | 80Kg | 80Kg | 56.5Kg | 45Kg | |

Aolong Group is a high-tech private enterprise with more than 50 years history and has powerful comprehensive technology strength. Aolong Group is not only the professional developer and manufacturer for radiograpny equipment and material testing instrument, but also the supplier of the application solution for the inspecting instrument.

Aolong Certificate

ISO9000 International quality system certificate

ISO14001 International environment system certificate

DHSAS18001 International career health & safety management system certificate

CE certificate

Packing details

Each product will be packed in cartons or wooden cases (we also accept customers' demands)

Delivery time

1. For sample order, 3-5 working days

2. For mass production, 5-7 weeks (It also depends on the order quantity and design)