For diameter 810mm~1440mm X-ray Pipeline Inspection Crawler

- Aolong

- China

- 15 days

- 1500pc/year

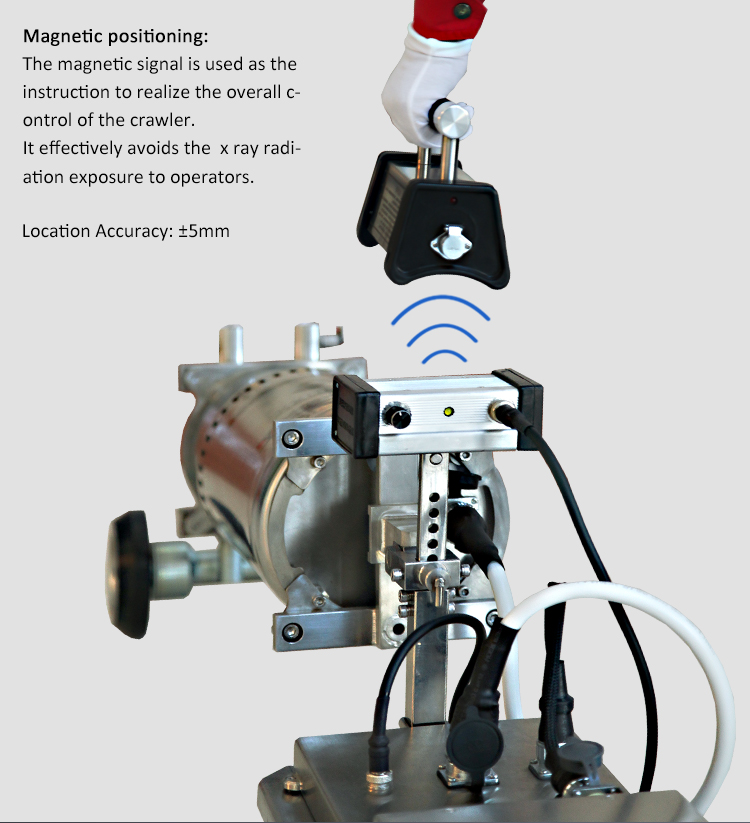

The control center of pipeline x-ray inspection equipment adopts Siemens S7-200 type programmable PLC, its positioning system adopts advanced magnetism positioning method which makes the product have many advantages, such as high integration, big memory, high coefficient of safety, high security, high sensibility and reliability.

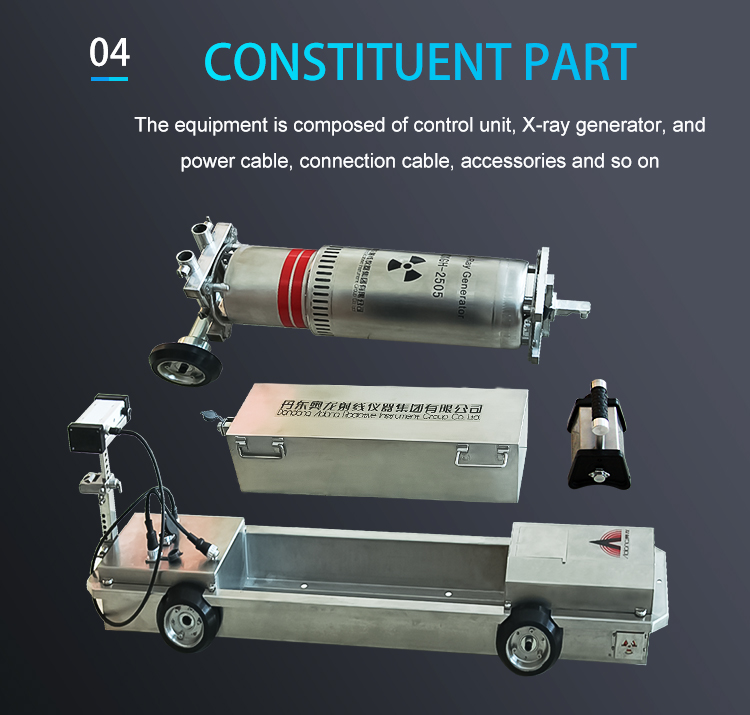

Pipeline X-ray Inspection Equipment mainly by mechanical parts, x-ray, positioning sensors, logic controllers, power supply and pipeline external source remote location using instructions, etc.

Pipeline inspection equipment is a kind of automatic X-ray generating device, crawling by the mechanical part drive X-ray generator crawling inside the pipeline, outside the pipe butt weld location special x-ray film and tag, through the cooperation of the external remote control device of the pipeline, positioning and exposure can be carried out in the pipeline, so as to carry out X-ray penetration of the pipeline butt girth weld and realize the non-destructive detection of the pipeline butt girth weld.

Pipeline X-ray Inspection Equipment magnetic positioning system, positioning system replace gamma-ray sources to reduce staff labor intensity, elimination of gamma ray source and harm to personnel, environment, pipeline crawler positioning control technology developing rapidly in recent years, has now been completely can replace gamma ray source with magnetic positioning control technology positioning control technology, uses the field instead of gamma ray transmission pipe wall,The positioning control precision and stability are similar to those of γ -ray source.

Technical Parameters

| AL-100A | AL-100B | AL-100C | AL-100D | AL-100E | ||

| Item | Parameters | Parameters | Parameters | Parameters | Parameters | |

| Range of Pipe Diameter | φ810-1440mm | φ710-1219mm | φ410-1016mm | φ219-510mm | φ219-510mm | |

| Max.Penetration(A3 Steel) | 42mm | 35mm | 30mm | 24mm | 24mm | |

| Tube(Cone) | Max.Out Voltage | 350kv | 300kv | 250kv | 200kv | 200kv |

| Max.Out Current | 3mA | 3mA | 3mA | 3mA | 3mA | |

| Focal Size | 1.0×2.3mm | 1.0×3.5mm | 1.0×2.0mm | 1.0×2.0mm | 1.0×2.0mm | |

| Beam | 360°×30° | 360°×30° | 360°×30° | 360°×30° | 360°×30° | |

| Environment Temperature | ‘-30°-80° | ‘-30°-80° | ‘-30°-80° | ‘-30°-80° | ‘-30°-80° | |

| Relative Humidity | ≤90% | ≤90% | ≤90% | ≤90% | ≤90% | |

| Energy Capacity of Battery | 120V,20Ah | 110V,22Ah | 106V,22Ah | 110V,10Ah | 96V,10Ah | |

| Crawling Ability | ≤45° | ≤45° | ≤45° | ≤45° | 30°-40° | |

| Location Accuracy | ±5mm | ±5mm | ±5mm | ±5mm | ±5mm | |

| Crawling Distance | 8Km(round trip) | 8Km(round trip) | 8Km(round trip) | 6Km(round trip) | 6Km(round trip) | |

| Crawling Speed | 16-18m/min | 16-18m/min | 16-18m/min | 16-18m/min | 16-18m/min | |

| Dimension (Crawler Vehicle) | 1400×400×219mm | 1250×270×180mm | 1200×300×190mm | 1180×230×160mm | 1600×140×140mm | |

| Tuming Radius | >70° | >70° | >70° | >70° | ≥10D | |

| Total Weight | 165Kg | 80Kg | 80Kg | 56.5Kg | 45Kg | |

Convincing inspection solition supplier

More than 50 years, Aolong Group focuses on the Non-destructive Testing Technologies and gives our customers the best inspection solution with the high quality radiographic equipment with simple operation and complete functions.

Aolong Certificate

ISO9000 International quality system certificate

ISO14001 International environment system certificate

DHSAS18001 International career health & safety management system certificate

CE certificate

Packing details

Each product will be packed in cartons or wooden cases (we also accept customers' demands)

Delivery time

1. For sample order, 3-5 working days

2. For mass production, 5-7 weeks (It also depends on the order quantity and design)