For diameter 710mm~1219mm Pipeline Crawler X-Ray Systems

- Aolong

- China

- 15 days

- 1500pc/year

Pipeline Crawler X-Ray System adopts our company's independent designed constant tube current control system, completely solves the problems of battery power reducing and film bad resolution of traditional pipeline inspection crawler.

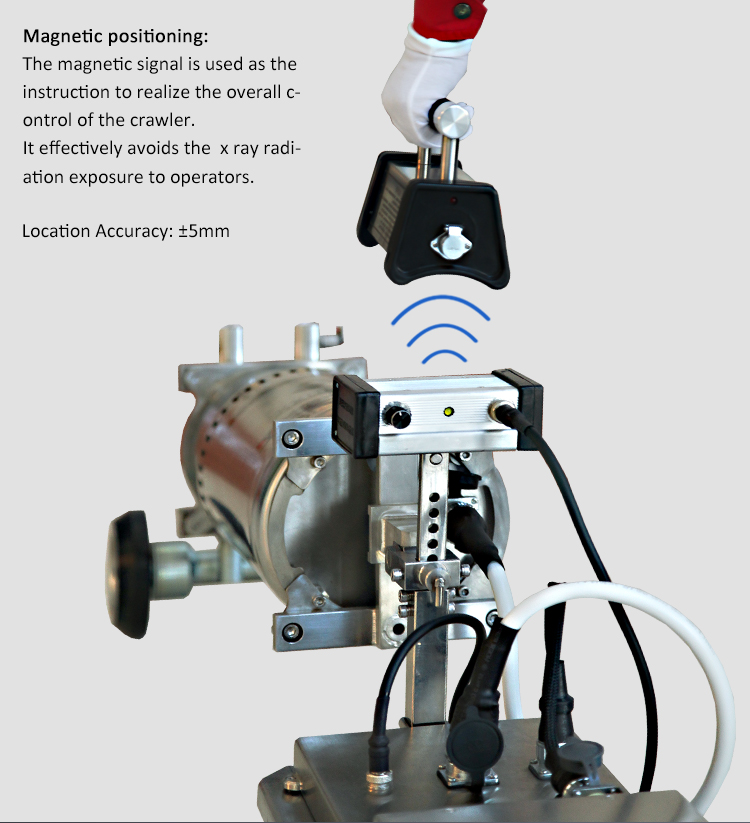

Magnetic positioning receiver is the core part of the whole pipeline crawler x-ray systems, which is directly related to the anti-interference ability, sensitivity, stability and reliability of magnetic positioning system.

Magnetic positioning can realize remote measurement of small volume object in pipeline, and its related electronic circuit is easy to realize. The relevant electromagnetic theory and many magnetic field detection methods provide a good technical support for this positioning method.

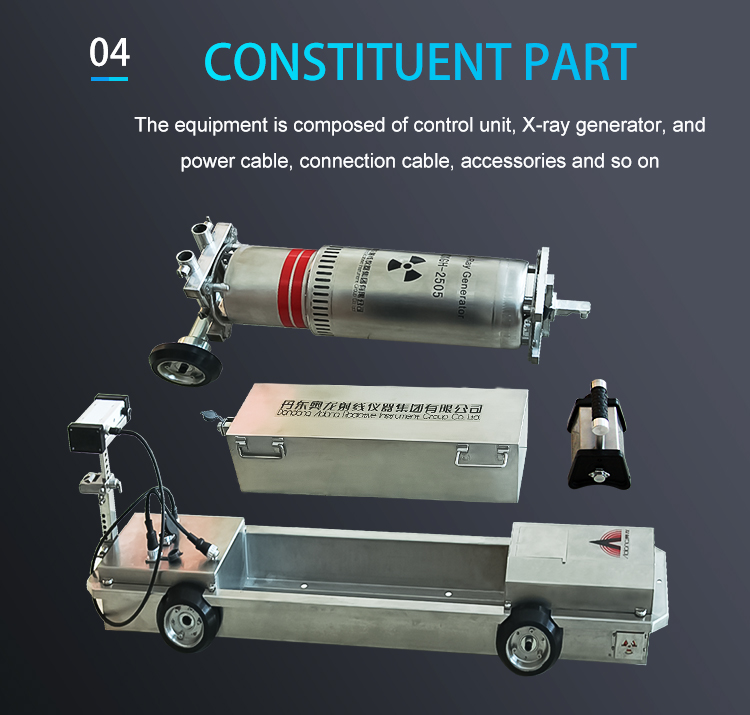

Pipeline x-ray Crawler is a testing equipment to take circumferential X-ray pictures of pipeline butt weld in pipeline laying engineering. A traction car is used to bring the circumferential X-ray inspection machine into the pipeline. When the ray emission window of the X-ray machine is aligned with the position of the welding joint, the magnetic receiving sensor is used to make the X-ray machine expose the welding joint in the pipeline according to the set exposure voltage and exposure time. Because the circumferential X-ray flaw detection machine is used to expose in the inner center of the pipeline, with short focal length and single wall projection, the exposure of the whole welding joint can be completed in one exposure.

Compared with the dual-wall projection method of the directional x-ray machine, the work efficiency can be improved dozens of times.The movement of the tractor inside the pipe is controlled by the magnetic emitter control box outside the pipe to complete the forward, backward, stop, exposure and other actions.

Technical Parameters

| AL-100A | AL-100B | AL-100C | AL-100D | AL-100E | ||

| Item | Parameters | Parameters | Parameters | Parameters | Parameters | |

| Range of Pipe Diameter | φ810-1440mm | φ710-1219mm | φ410-1016mm | φ219-510mm | φ219-510mm | |

| Max.Penetration(A3 Steel) | 42mm | 35mm | 30mm | 24mm | 24mm | |

| Tube(Cone) | Max.Out Voltage | 350kv | 300kv | 250kv | 200kv | 200kv |

| Max.Out Current | 3mA | 3mA | 3mA | 3mA | 3mA | |

| Focal Size | 1.0×2.3mm | 1.0×3.5mm | 1.0×2.0mm | 1.0×2.0mm | 1.0×2.0mm | |

| Beam | 360°×30° | 360°×30° | 360°×30° | 360°×30° | 360°×30° | |

| Environment Temperature | ‘-30°-80° | ‘-30°-80° | ‘-30°-80° | ‘-30°-80° | ‘-30°-80° | |

| Relative Humidity | ≤90% | ≤90% | ≤90% | ≤90% | ≤90% | |

| Energy Capacity of Battery | 120V,20Ah | 110V,22Ah | 106V,22Ah | 110V,10Ah | 96V,10Ah | |

| Crawling Ability | ≤45° | ≤45° | ≤45° | ≤45° | 30°-40° | |

| Location Accuracy | ±5mm | ±5mm | ±5mm | ±5mm | ±5mm | |

| Crawling Distance | 8Km(round trip) | 8Km(round trip) | 8Km(round trip) | 6Km(round trip) | 6Km(round trip) | |

| Crawling Speed | 16-18m/min | 16-18m/min | 16-18m/min | 16-18m/min | 16-18m/min | |

| Dimension (Crawler Vehicle) | 1400×400×219mm | 1250×270×180mm | 1200×300×190mm | 1180×230×160mm | 1600×140×140mm | |

| Tuming Radius | >70° | >70° | >70° | >70° | ≥10D | |

| Total Weight | 165Kg | 80Kg | 80Kg | 56.5Kg | 45Kg | |

Dandong Aolong Radiative Instrument Group Co.,Ltd. occupies 30 thousand square meters, and the construction area is 17 thousand square meters, owning international modern advanced manufacturing conditions and research, manufacture and test facilities. We are the leading radiography manufacturer and service application provider.

Aolong Certificate

ISO9000 International quality system certificate

ISO14001 International environment system certificate

DHSAS18001 International career health & safety management system certificate

CE certificate

Packing details

Each product will be packed in cartons or wooden cases (we also accept customers' demands)

Delivery time

1. For sample order, 3-5 working days

2. For mass production, 5-7 weeks (It also depends on the order quantity and design)